Rattlesnake Mountain is yet another steep trap rock ridge, part of the Metacomet range that includes The Hanging Hills and Mt. Higby. After reading about it on the CtMuseumquest web page, I went looking for Hospital rock. Very fortunately, someone has placed a cache near the rock, providing coordinates.

Parked on Metacomet Road, after passing many "No Parking" signs, at what seemed like a safe spot. The trail head leads to this remnant of a road:

Very eroded & steep,it climbs the full height of Rattlesnake Mountain in a few hundred yards.

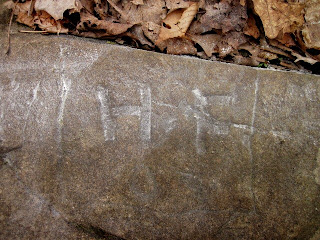

GPS brought me over a few dirt roads to the cache, which was only a few yards from Hospital Rock. The Rock is much more subtle that I'd expected. Somehow I was expecting a wide-open area on a prominence, but its in a flat, wooded area. One could walk right over it without noticing. The carvings themselves are very faint. You can highlight them by brushing them with flour, and if someone hadn't done this recently, I wouldn't have noticed them at all. I brought my own flour & brush, and dusted until I ran out of flour.

And the Neatest Carving Award goes to:

Back to the trail for another cache, this one near one of those old Nike Missile sites. The Trail goes right over it.

Lots of rusted fencing about.

And a nice view of a toney neighborhood:

Saturday, April 20, 2013

Saturday, April 6, 2013

Glassing The Deck

Even the parts of the project that I expect to go "routinely", sometimes have problems. They must be "routine" problems.

I got a few ripples. One day, I will figure out what exactly causes this.

Jay's building manual advocates glassing all parts, then glassing in a strip on the outside. Instead, I left the top of the deck un-glassed, and masked an overhand, as on my last two builds. My choice of masking tape (filament) was slightly better than the last time, but this time I had to pull off left-over filaments.

I got a few ripples. One day, I will figure out what exactly causes this.

Jay's building manual advocates glassing all parts, then glassing in a strip on the outside. Instead, I left the top of the deck un-glassed, and masked an overhand, as on my last two builds. My choice of masking tape (filament) was slightly better than the last time, but this time I had to pull off left-over filaments.

Wednesday, March 27, 2013

Closing The Clam

This was a bit more tedious than expected.

I had considered cutting strips of 4 ounce fiberglass, but broke down and got a roll of 9 ounce tape. Here its tacked to the inside hull with hot-melt glue.

The deck is still unglassed. Some epoxy did come through the deck, but I think I can deal with it.

It was hard to get the deck & hull to match up. Pushing the hull up to the deck was much easier than trying to pull the hull out to meet the deck. I posted a "help" message on the ConYak Builder's Forum. I mainly got a lot of complicated suggestions, but one worked: I made a 2x6" strip of aluminum (roof flashing) with a 90 degree bend at the end. I slid it into the gap, and pulled out on the hull while taping the halves together.

My Thule racks have been pressed into service to hold the boat on end. I have the famous Brush On A Stick attached to a long stick. This would have been much easier to reach if the hatches were cut, but I want to glass the entire deck before cutting hatches.

I had almost forgotten how greedily 9 ounce tape drinks epoxy. I also found that the size of the brush wouldn't allow me to spread the epoxy to the bitter ends of the bow & stern, but I think I can reach it later, once the hatches are cut.

After getting halfway through, I realized that I'd forgotten about gluing the the deck down at the tips. I rushed to un-tape the ends together, and woked some glue into the gap with a brush. A "whew" moment.

I had considered cutting strips of 4 ounce fiberglass, but broke down and got a roll of 9 ounce tape. Here its tacked to the inside hull with hot-melt glue.

The deck is still unglassed. Some epoxy did come through the deck, but I think I can deal with it.

It was hard to get the deck & hull to match up. Pushing the hull up to the deck was much easier than trying to pull the hull out to meet the deck. I posted a "help" message on the ConYak Builder's Forum. I mainly got a lot of complicated suggestions, but one worked: I made a 2x6" strip of aluminum (roof flashing) with a 90 degree bend at the end. I slid it into the gap, and pulled out on the hull while taping the halves together.

I had almost forgotten how greedily 9 ounce tape drinks epoxy. I also found that the size of the brush wouldn't allow me to spread the epoxy to the bitter ends of the bow & stern, but I think I can reach it later, once the hatches are cut.

After getting halfway through, I realized that I'd forgotten about gluing the the deck down at the tips. I rushed to un-tape the ends together, and woked some glue into the gap with a brush. A "whew" moment.

Tuesday, March 19, 2013

Deck Underside

Fairly routine. I had to resort to some microbaloon filler in the area just behind the cockpit, because I'd have run out of wood. I'll definitely use thicker strips the next time.

Sunday, March 10, 2013

Glassing The Bottom

Since my hull came out a little thin, I decided on a little more reinforcement than on my last build. I made a piece that was part "football" and part end strip. I have noticed that scratches from grounding happen most often directly under the waterline. The reinforcing strips that go all the way up the stem & stern don't really do anything.

Since my hull came out a little thin, I decided on a little more reinforcement than on my last build. I made a piece that was part "football" and part end strip. I have noticed that scratches from grounding happen most often directly under the waterline. The reinforcing strips that go all the way up the stem & stern don't really do anything. I also took Jay Babina's advice, and put the small piece under the big one. This absolutely works better- no strings or fuzz, it all blends right together.

The glassing seemed to go well, but I had forgotten how much epoxy a double layer will drink up.

The glass did ripple under the double layer. I don't know if it was just because it was double, or because the small piece is underneath. I haven't had this happen since my first build. At least I know what to do about it-grind, scrape, coat, etc.

Thursday, February 28, 2013

Hull Interior

As I suspected, it was a lot more work to get the hull interior smooth that it should have been. I started scraping & sanding away it it yesterday, and I ditched work, determined to finish. I resorted to putty fills in the dangerously-thin areas.

I decided to actually follow the instructions, and do the bow & stern areas first.

Its getting easier. Both ends took a little more than an hour, and it seemed less frustrating than the last time I glassed.

Its getting easier. Both ends took a little more than an hour, and it seemed less frustrating than the last time I glassed.

The glass in between the ends went down fairly well also. I gave it two fill coats, sanded & varnished. I decided to paint the areas that will be visible inside the hatches.

This shows how it will look when finished-a little more "stripey" than I expected.

I decided to actually follow the instructions, and do the bow & stern areas first.

Its getting easier. Both ends took a little more than an hour, and it seemed less frustrating than the last time I glassed.

Its getting easier. Both ends took a little more than an hour, and it seemed less frustrating than the last time I glassed. The glass in between the ends went down fairly well also. I gave it two fill coats, sanded & varnished. I decided to paint the areas that will be visible inside the hatches.

This shows how it will look when finished-a little more "stripey" than I expected.

Monday, February 25, 2013

Geocaching

Every Solution needs a Problem. I bought a small, waterproof GPS unit, and decided to try some geocaching.After the usual new-gizmo frustration, I managed to find a website & download a cache.

I found this after some more slightly comical learning-curve stuff.

It was well-packed. The trash bag was a nice idea. I didn't see any trash on the trail, so I took the bag to place in the next cache I visit.

I found this after some more slightly comical learning-curve stuff.

It was well-packed. The trash bag was a nice idea. I didn't see any trash on the trail, so I took the bag to place in the next cache I visit.

Sunday, February 24, 2013

Cockpit Cutout

Here is the rough opening of the cockpit. I was right when I thought that it was a steep drop from the foredeck to the aft-it still is, with the area in wood. I don't think I'll be able to raise the coaming the way I did on the Shearwater, with 1/4" plywood, I'm going to have to "Improvise".

Also, I had just enough wood left after fairing the area behind the cockpit. I didn't quite get the strips down to the level of form 10.5. I'm going to have to reinforce the area from the inside, and raise the height of the aft bulkhead a little.

Also, I had just enough wood left after fairing the area behind the cockpit. I didn't quite get the strips down to the level of form 10.5. I'm going to have to reinforce the area from the inside, and raise the height of the aft bulkhead a little.

Monday, February 18, 2013

The Last Plank

Normally, this would be called "The Whiskey Plank", but I decided on "temperance" for two reasons: First, I had a stomach virus when I did it, and couldn't bear the thought of whiskey, and Second, there were so many, irregular, custom shaped boards in this build, that if I had a shot every time I put one in, I'd be in rehab now.

I can also see that I'm going to have to do a lot of corrective sanding & shaping. Oh well...

I can also see that I'm going to have to do a lot of corrective sanding & shaping. Oh well...

Tuesday, February 12, 2013

Deck, Continued

I was right in thinking that it was a heck of a drop from the extended front form to the rear deck. I couldn't really visualize it until I started working full-length strips on the sides.

I used the heat-bending technique, as for the stem & stern strips. I also offset the strips a little, like ship lap, to make it down to the deck. In future builds, I'll use the full 1/4" thickness for the strips, so I won't have to worry as much about running out of wood while fairing.

I can better see what has to happen now. I even resorted to a couple of screws to hold it down.

I also have committed to using the long cockpit opening. After weighing the Pros & Cons, I decided that I'd rather be comfortable than 100% aesthetic.

I used the heat-bending technique, as for the stem & stern strips. I also offset the strips a little, like ship lap, to make it down to the deck. In future builds, I'll use the full 1/4" thickness for the strips, so I won't have to worry as much about running out of wood while fairing.

I can better see what has to happen now. I even resorted to a couple of screws to hold it down.

I also have committed to using the long cockpit opening. After weighing the Pros & Cons, I decided that I'd rather be comfortable than 100% aesthetic.

Monday, January 28, 2013

More Deck Stripping

This is actually my second "go" at the deck. I removed the few center strips seen in the previous post. I had trouble getting them straight, and they were too thin, anyway.

I milled some new strips. I found lumber that showed a fairly straight grain from the side, and plain-sawed the strips. Much easier than all that re-sawing! I also learned that slightly thicker strips are more "forgiving" in joinery.

The part where the strips curve from the shear to the flat deck is a bear ! I ended up using 3/8" strips, and it seemed to take forever to get the tapering right. I got more practice using the heat gun to bend strips.

I'm finding that its easier to visualize certain things better while in progress, than in advance. For example, the big curve from the foredeck to the after deck looks "impossible" until you begin to do it, then it graduates to "difficult". For this reason, I still haven't decided which cockpit size to use, because I can't visualize how it will look without the wood in place.

I milled some new strips. I found lumber that showed a fairly straight grain from the side, and plain-sawed the strips. Much easier than all that re-sawing! I also learned that slightly thicker strips are more "forgiving" in joinery.

The part where the strips curve from the shear to the flat deck is a bear ! I ended up using 3/8" strips, and it seemed to take forever to get the tapering right. I got more practice using the heat gun to bend strips.

I'm finding that its easier to visualize certain things better while in progress, than in advance. For example, the big curve from the foredeck to the after deck looks "impossible" until you begin to do it, then it graduates to "difficult". For this reason, I still haven't decided which cockpit size to use, because I can't visualize how it will look without the wood in place.

Wednesday, January 2, 2013

Starting The Deck

After some consideration and consultation, I decided to raise the deck 1", and go with the design Ocean Cockpit. Sometimes, I just have to make up my mind-I can build all the kayaks I want!

Per recommendation, I made form extensions. I also saw that if I kept the same shape on the sides of the extensions, it looked like a "wall" rising up from the sheerline, so I rounded the corners off a little. It seemed that three form extensions were adequate for a fair deck curve. The 1" lift looks considerable, and it looks like quite a drop down to the rear deck level.

I joined two 3/8" strips together at the center line. One 3/4" strip looked almost good, but I wanted to bevel slightly on the forms that are curved. The usual array of clamps and tape.

Per recommendation, I made form extensions. I also saw that if I kept the same shape on the sides of the extensions, it looked like a "wall" rising up from the sheerline, so I rounded the corners off a little. It seemed that three form extensions were adequate for a fair deck curve. The 1" lift looks considerable, and it looks like quite a drop down to the rear deck level.

I joined two 3/8" strips together at the center line. One 3/4" strip looked almost good, but I wanted to bevel slightly on the forms that are curved. The usual array of clamps and tape.

Saturday, December 22, 2012

Bending Keel Strips.

After trimming the bow & stern keel end with a plane, I found the bends to be more extreme than I thought. 1/4" strips of pine and cedar would not make the bend without snapping. I went to 1/8" strips, and yellow cedar almost made the turn, but not without brute force.

I decided to try heat bending. After some advice, practice,trial, and error, got some results with 1/8" pine.

It seems as though the wood won't begin to bend until it is also about ready to burn. With some practice I got the stern keel strips done.

A typical barrage of tapes, staples, and brads to get it in place.

Happily the bow strips go down without any need for heat bending.

I'm glad I had a chance to practice this technique on the bottom, before I start the deck.

I laid up 3 1/8"x3/4" strips, and one 1/8"x3/8" strip on each end.

After some planing & sanding, I think that the 3/8" strip may not have even been necessary. I'm trying to sand the keel strips to blend into the 1/4" pine keel strip.

I decided to try heat bending. After some advice, practice,trial, and error, got some results with 1/8" pine.

It seems as though the wood won't begin to bend until it is also about ready to burn. With some practice I got the stern keel strips done.

A typical barrage of tapes, staples, and brads to get it in place.

Happily the bow strips go down without any need for heat bending.

I'm glad I had a chance to practice this technique on the bottom, before I start the deck.

I laid up 3 1/8"x3/4" strips, and one 1/8"x3/8" strip on each end.

After some planing & sanding, I think that the 3/8" strip may not have even been necessary. I'm trying to sand the keel strips to blend into the 1/4" pine keel strip.

Filling In The Bottom

I decided to try Vaclav's technique for filling in large areas where where the full-length shear strips meet the strips laid parallel to the keel. I let the ends fall short:

Then I used a full-length 1/2" strip to mark the cutout. I had little faith in my ability to follow the line with a saw, so I stapled it on & used it for a cutting guide:

This was harder than I thought. This technique requires a lot of skill with the saw. My pullsaw was too aggressive, so I resorted to multiple passes with a utility knife. This unfortunately gave a sort of V-shaped cut.

Planing the strip was more difficult than I thought it would be. At one point, the tapered strip would fit in like a wedge, but pull a neighboring section too far apart, etc,

The strip in place. It was not exactly a "Voila!" moment. Some gaps that will need to be filled. After all, I think It might have been better to fit each end. I dont think I'll be trying this on the deck.

Then I used a full-length 1/2" strip to mark the cutout. I had little faith in my ability to follow the line with a saw, so I stapled it on & used it for a cutting guide:

This was harder than I thought. This technique requires a lot of skill with the saw. My pullsaw was too aggressive, so I resorted to multiple passes with a utility knife. This unfortunately gave a sort of V-shaped cut.

Planing the strip was more difficult than I thought it would be. At one point, the tapered strip would fit in like a wedge, but pull a neighboring section too far apart, etc,

The strip in place. It was not exactly a "Voila!" moment. Some gaps that will need to be filled. After all, I think It might have been better to fit each end. I dont think I'll be trying this on the deck.

Sunday, December 16, 2012

Still Stripping The Hull

After having reached the first & last forms with full-length strips, I ran a 1/4 x1/4 pine strip the length of the keel, nailing it in with brads. I used a string line, stretched it straight, and generally ignored the center marks on the forms. It came out pretty fair, except for a lump around form #16.

I then ran the strips parallel to the center strip. This seemed ridiculously easy compared to the long strips near the sheer line. The lie much flatter, only a slight taper needed, and they naturally get shorter as I go along. I left the ends unfitted, since I want to try Vaclav's technique for "filling in large areas". More about that later.

My most-used tool for holding strips in place is plain old filament tape. It fits into small spaces, and you can really get a good squeeze with it, especially with multiple laps. I'm not an anti-staple purist, but I sometimes found that they don't really hold strips under a lot of tension.

I then ran the strips parallel to the center strip. This seemed ridiculously easy compared to the long strips near the sheer line. The lie much flatter, only a slight taper needed, and they naturally get shorter as I go along. I left the ends unfitted, since I want to try Vaclav's technique for "filling in large areas". More about that later.

My most-used tool for holding strips in place is plain old filament tape. It fits into small spaces, and you can really get a good squeeze with it, especially with multiple laps. I'm not an anti-staple purist, but I sometimes found that they don't really hold strips under a lot of tension.

Wednesday, December 5, 2012

Even More Stripping

Having finally filled the boat up to the waterline strip, I decided that if I build another stripper, I will not use a waterline strip.

I posted this picture because I think it is the first stage where it finally begins to have some curvature and shape that suggests some kind of boat. The usual barrage of L-shaped brackets and clamps. I found that filament tape works well to hold the strips together.

I'm surprised at how much easier is it to improvise on the second strip-job than the first.

Also pleased that the strips from both sides came together fairly evenly, to a workable V shape. I laid a 1/4" pine board down the keel line. Again, I found that if I followed the lines on the forms exactly, I came out with perceptible squiggles, so I stretched it straight down the keel line, and tacked it down with brads.

I also started planing the ends down to the forms. I have some cypress strips that were for the shear clamps of my Hybrid-I may try making keel strips of them.

I posted this picture because I think it is the first stage where it finally begins to have some curvature and shape that suggests some kind of boat. The usual barrage of L-shaped brackets and clamps. I found that filament tape works well to hold the strips together.

I'm surprised at how much easier is it to improvise on the second strip-job than the first.

Also pleased that the strips from both sides came together fairly evenly, to a workable V shape. I laid a 1/4" pine board down the keel line. Again, I found that if I followed the lines on the forms exactly, I came out with perceptible squiggles, so I stretched it straight down the keel line, and tacked it down with brads.

I also started planing the ends down to the forms. I have some cypress strips that were for the shear clamps of my Hybrid-I may try making keel strips of them.

Saturday, November 24, 2012

More Stripping

I decided to use a different-colored strip along the waterline. As I thought , it earned me a lot of work. All the instruction about laying parallel strips, then filling the bow & stern ends with a few "filler strips" kind of goes out the window-I now have to use lots of tapered strips to match both the curve of the ends, and the curve of the waterline.

I think/hope it gets easier after this....

I think/hope it gets easier after this....

Saturday, November 3, 2012

The First Strip

I think I'll hold off on the next picture until I can take one that shows more progress.

This was a tough day. My DSL modem blew up, spent half the day getting a new one to behave.

While making an adjustment to the Bow Form, the right-angle bracket that holds it on the strongback broke. I re-glued it with epoxy, and that, too, broke. I screwed it together, then discovered that all the reference marks that I made were now useless- I had to construct a new jig for a string line , re-level, re-plumb, and re-align the thing.

Then I tried taking the first strip along the shear line. Again, it showed waves & curves when aligned exactly on the marks. I removed and replaced nails until the whole strip looked fair. The strip came within 1mm of the marks everywhere, and I figured that there was no point in building strictly to the forms if some of them are misaligned.

I used a 1/2" strip, and had no problem making the curves at the bow & stern.

11-10-12

I couldn't exactly bring myself to post a photo of one strip on the forms.

as usual, I'm figuring it out as I go along. My idea this time, was to "take as long as it takes", which is good, but it also results in "glacial progress". At times, I feel like I'm making a Federal Case out of it.

I decided on a light-colored (pine) strip at the Waterline mark. It looks nice, but it also sort of cancels out some of the instructions I've read, like adding filler strips at the bow & stern until parallel strips can be laid to the shear line. I'm going to be doing a lot of trimming & fitting of strips.

This was a tough day. My DSL modem blew up, spent half the day getting a new one to behave.

While making an adjustment to the Bow Form, the right-angle bracket that holds it on the strongback broke. I re-glued it with epoxy, and that, too, broke. I screwed it together, then discovered that all the reference marks that I made were now useless- I had to construct a new jig for a string line , re-level, re-plumb, and re-align the thing.

Then I tried taking the first strip along the shear line. Again, it showed waves & curves when aligned exactly on the marks. I removed and replaced nails until the whole strip looked fair. The strip came within 1mm of the marks everywhere, and I figured that there was no point in building strictly to the forms if some of them are misaligned.

I used a 1/2" strip, and had no problem making the curves at the bow & stern.

11-10-12

I couldn't exactly bring myself to post a photo of one strip on the forms.

as usual, I'm figuring it out as I go along. My idea this time, was to "take as long as it takes", which is good, but it also results in "glacial progress". At times, I feel like I'm making a Federal Case out of it.

I decided on a light-colored (pine) strip at the Waterline mark. It looks nice, but it also sort of cancels out some of the instructions I've read, like adding filler strips at the bow & stern until parallel strips can be laid to the shear line. I'm going to be doing a lot of trimming & fitting of strips.

Wednesday, October 24, 2012

Strongback

As stated in my earlier post, I gave up on the laid-up-plywood idea, and got a 2x6 and a 2x4. Much more rigid & straight, but it too, weighs "tons". The patterns are stuck to the other sides of the forms. Fairly straightforward to put together, and as usual, I "got good at it" by about Form 14. One error: I thought that a 6" width would make a nice, hefty platform, and it does, but Form # 2 was less than 6" wide, so I had to do some

Creative Carving. It gets less scary a few days after its completed. It looks pretty much like everybody else's picture of a strongback, so I must be doing something right.

11-1-12

Well, I was doing "something right, but not everything. In case I hadn't mentioned it yet, I decided to build this kayak at 96% of the design length. I usually remembered this, but not always-for example, I diligently lined Form #1 on the marks, forgetting that the position would be different on a shorter boat. As per the instructions, I placed strips along the shear line of all the forms, and found that I had to reposition four forms, including the bow form. I had no idea until I placed a strip on the forms.

I tried test strips on both shear lines, both waterlines, and 2 strips on the keel line. I think Its right.

Creative Carving. It gets less scary a few days after its completed. It looks pretty much like everybody else's picture of a strongback, so I must be doing something right.

11-1-12

Well, I was doing "something right, but not everything. In case I hadn't mentioned it yet, I decided to build this kayak at 96% of the design length. I usually remembered this, but not always-for example, I diligently lined Form #1 on the marks, forgetting that the position would be different on a shorter boat. As per the instructions, I placed strips along the shear line of all the forms, and found that I had to reposition four forms, including the bow form. I had no idea until I placed a strip on the forms.

I tried test strips on both shear lines, both waterlines, and 2 strips on the keel line. I think Its right.

Monday, October 8, 2012

Plans For An Outer Island

I have firmly decided to build an Outer Island. Reasons:

1. I had been searching for a kayak that most closely resembled my Shearwater. After looking at Siskwit Bay, Disko Bay, and Night Heron, this boat was suggested on a message board. I had read that the Siskwit Bay was "not that fast". I simply could not stand the name of the Disko Bay. All I could think of was a Frank Zappa song ( Disko Baayyyy!) I tried the Heron at a demo & hated it. Then, as per my earlier post, I had the amazing luck of meeting Jay Babina by chance, and trying his OI.

2. I like the name. I like the fact that its named after a local place that's familiar to me, not someplace in Washington or Delaware, and its not named after a bird.

3. Not designed by You-Know-who.

The plans, and building notes are very good-all the information you need, without any unnecessary wit or opinions.

I resorted to using the table saw in my driveway, since my Shearwater had a coat of paint drying in the basement. Actually not a bad place to work, as long as the weather cooperates.

I'm working on the strongback here. I got some 3/4" sanded poplar plywood, figuring to lay up a double-thickness plank. I realized a day later that I'd cut it too short. I wasn't too disappointed, however, because it was very heavy & bendy anyway. I snapped out of it the next day and bought dimension lumber.

1. I had been searching for a kayak that most closely resembled my Shearwater. After looking at Siskwit Bay, Disko Bay, and Night Heron, this boat was suggested on a message board. I had read that the Siskwit Bay was "not that fast". I simply could not stand the name of the Disko Bay. All I could think of was a Frank Zappa song ( Disko Baayyyy!) I tried the Heron at a demo & hated it. Then, as per my earlier post, I had the amazing luck of meeting Jay Babina by chance, and trying his OI.

2. I like the name. I like the fact that its named after a local place that's familiar to me, not someplace in Washington or Delaware, and its not named after a bird.

3. Not designed by You-Know-who.

The plans, and building notes are very good-all the information you need, without any unnecessary wit or opinions.

I resorted to using the table saw in my driveway, since my Shearwater had a coat of paint drying in the basement. Actually not a bad place to work, as long as the weather cooperates.

I'm working on the strongback here. I got some 3/4" sanded poplar plywood, figuring to lay up a double-thickness plank. I realized a day later that I'd cut it too short. I wasn't too disappointed, however, because it was very heavy & bendy anyway. I snapped out of it the next day and bought dimension lumber.

Subscribe to:

Posts (Atom)